SAP MANUFACTURING PROCESS

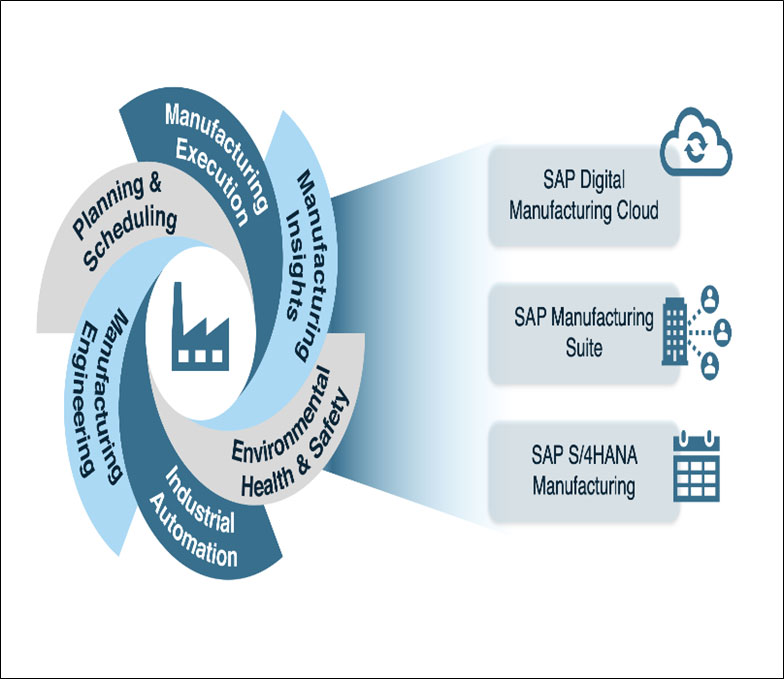

Connected machines are only the first step in making the digital factory a reality. To capture real, lasting business value, companies need to collect and analyze the process data produced by their plant machinery in real time.

SAP Digital Manufacturing is a data-driven shop-floor manufacturing execution solution that enables key stakeholders to manage and produce high quality products with best-in-class manufacturing visibility and error-proof operation.

With planning, manufacturing, and execution solutions from SAP, businesses can centralize all their manufacturing operations on one platform to connect demand forecasting and production scheduling, materials management, shop floor execution, and quality control.

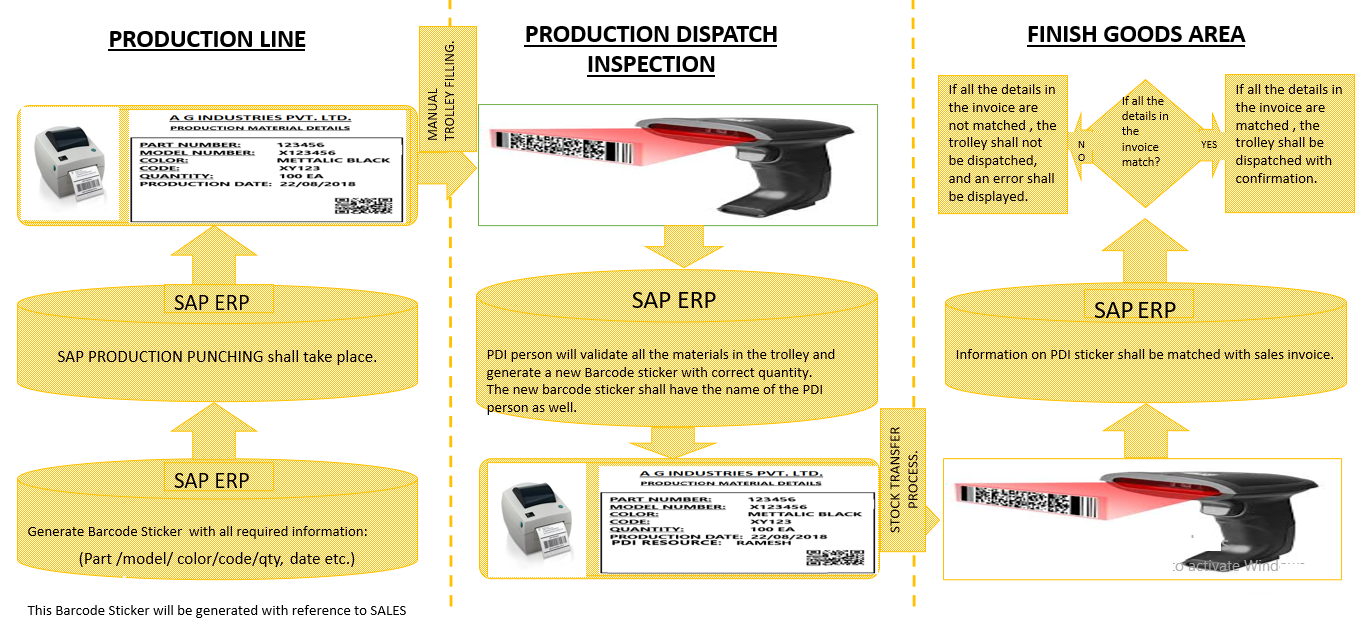

PREMIUM CLIENTS

Exchimious had used personal expertise and acumen of it’s internal SAP PP and SAP PM consultants to digitalize

full scale inventory process. It contributed immensely and helped client to:

- Manage their raw material, semi-finished goods and outgoing finished goods.

- Less paperwork and data record at each level was improvised and led to 30% efficiency in overall process.

- Internal SAP screens were used and a provision was made adding additional digital interfaces as well

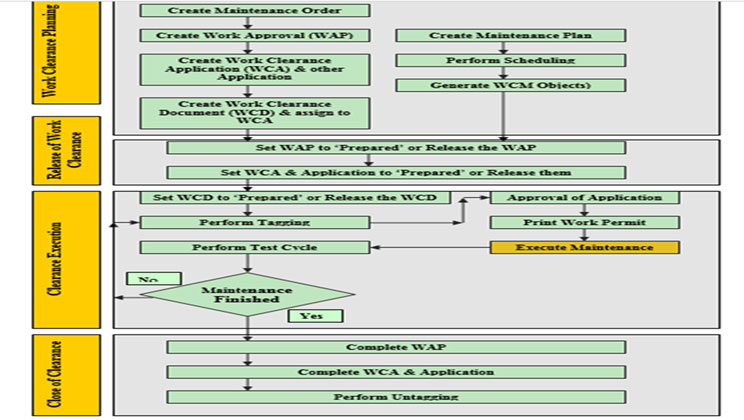

EXCHIMIOUS PLANT MAINTENANCE DIGITAL PROCESS

Individual statuses of operational phases are predefined in the system.

TAGGING PHASE

- Tag (BTG)

- Tag printed (PTAG)

- Tagged (ETG)

TEMPORARY UNTAGGING PHASE

- Untag temporarily (BTUG)

- Test tag printed (PTST)

- Temporarily untagged (ETUG)

UNTAGGING PHASE

- Untag (BUG)

- Untagged (EUG)

PROCESS FLOW